Water & Energy Efficiency

Water Stewardship and Energy Efficiency

APRIL Group has invested in processes and technology to ensure best practice water and energy efficiency.

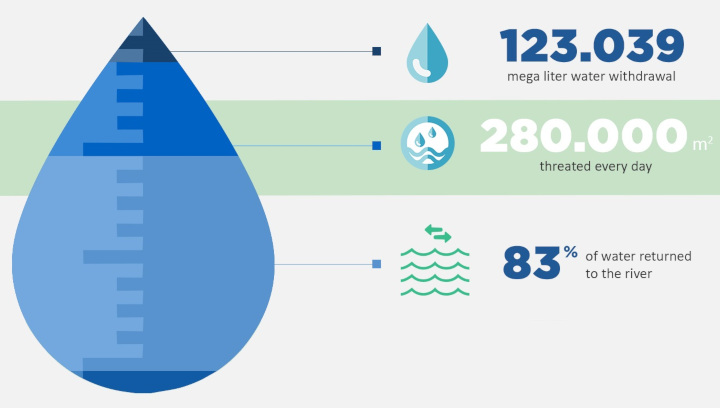

Water is used in almost every part of the pulp and paper making process. To produce quality pulp, clean water is essential. APRIL Group invests in water treatment technology to clean water taken from the river for mill usage. The benefits also with the local communities as APRIL Group provides clean water to the nearby Pangkalan Kerinci.

Approximately 83% of the withdrawn water is returned to the river as the result of innovative water treatment developed by an internal team of experts.

Energy Efficiency

APRIL Group has reduced dependence on fossil fuels by capturing and converting energy generated by its waste and production processes. Of APRIL Group’s total fuel energy consumption, 87% is now derived from biofuels and natural gases, reducing emissions as well as generating indirect benefits.

The most significant contributor to biofuel production is the operation one of the world’s largest recovery boiler that captures energy from black liquor, a product of the pulp making process, and converts it into energy. The energy from this and three other recovery boilers is used to produce steam for power generation and in the drying process for paper production.

Further energy efficiency is achieved through methanol capture, where methanol is captured through a process of distillation and evaporation involving black liquor. This is reused in kilns, again reducing the reliance on fossil fuels.

While much of this energy generation is directed at the pulp and paper manufacturing process, some is passed onto the local grid, providing local communities with an additional energy source.