With a designed capacity of 2.8 million tonnes of pulp and 820,000 tonnes of paper per year, APRIL’s Kerinci pulp and paper mill is rated in the top five in the world for efficiency.

APRIL complies rigorously with all Indonesian environmental regulations and our mill meets the EU IPPC directives to cut emissions using best available techniques (BAT) for the pulp and paper industry. From the outset, this mill was engineered to be world-class.

Our mill operation benefits Riau province and Indonesia in a number of ways. The mill adds considerable value to our plantation products and importantly, it does this in our local area of Riau province. This brings a range of benefits to the province, in areas such as positive economic impacts, skills training, opportunities for advancement.

At a national level, our pulp and paper mill helps reduce import reliance, with consequent reduced transport impacts and national economic benefits. It also brings competition to the domestic market.

Since our 2010 Sustainability Report and with our operations in Riau province well established, we have focused on optimising the performance of our mill. This has resulted in strong performance, a high level of efficiency and significant environmental benefits. These include reductions in materials and energy required to produce a given amount of product. With our mill running at designed capacity and no additional capacity planned, we continue to invest in better environmental initiatives.

For example, APRIL employs the Lean Manufacturing philosophy. This involves a constant drive for efficiency across all measures combined with a steady elimination of waste to ensure smooth running. Avoiding shutdowns and disruptions has been shown to achieve the best possible environmental outcomes in terms of energy requirements and emissions.

With a designed capacity of 2.8 million tonnes of pulp and 820,000 tonnes of paper per year, APRIL’S pulp and paper mill is rated in the top five in the world for efficiency.

Location

Operating a pulp and paper mill in Riau province Sumatra requires us to be self-sufficient and independent. This location brings a number of challenges in areas such as logistics, lack of power grid connection and absence of state-owned infrastructure. As a result, we operate with a high degree of vertical integration, from tree nursery and plantation to packaging and dispatch.

Our location also demands that we take special care of our employees. Accordingly, we have developed our own town site that is now home to more than 7000 people. Our town includes two schools (including an international school), a health clinic, sports facilities and a hotel.

But as well as challenges, there are considerable benefits to operating in Riau province.

Abundant Water Supply

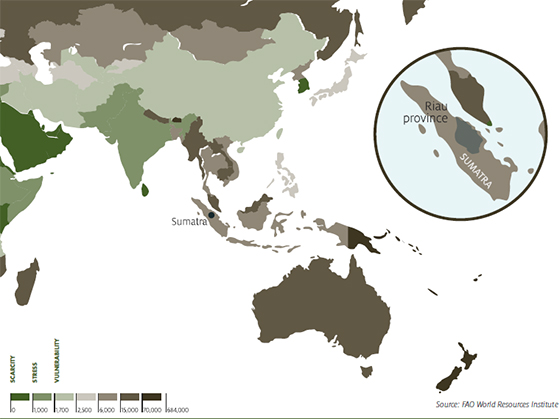

While water availability is becoming an issue of concern to many pulp and paper manufacturers, our location provides access to a plentiful water supply, in a region where water is abundant, as the map below shows. The impact of our water sourcing on the flow rate of our main water source, the Kampar River, is well below BAT limits. (See Figure 24).

Figure 7: MAP SHOWING GLOBAL WATER AVAILABILITY (M3/PERSON/YEAR)

Strong Pool of Potential Employees

Riau province also contains a large pool of potential employees who are keen to improve their lives through employment with our company.

They take advantage of our training systems, scholarships and other opportunities, which delivers good outcomes for the company, for individual employees and for the community more broadly.

We are proud of the fact that we are helping people in this way, and bringing prosperity to central Sumatra.

Proximity to Markets

Being at the heart of the fast growing Asia region means we can supply our markets with far less transport distance than European or American pulp and paper manufacturers.

Our location contributes to the objective of reducing transport emissions.

Impact on Surrounding Populations

The relative remoteness of our mill location limits the impact of our operations on major population centres.

It is recognized that even the most efficient pulp and paper mills have an impact on surrounding populations in areas such as transport and odours. This requires the development of management systems to mitigate these effects.

Best Available Technique (BAT)

To ensure ongoing high operating standards, we benchmark our pulp and paper mill against other leading mills, measuring our environmental performance against stringent European Union IPPC Best Available Techniques (BAT) recommended maximum and minimum levels. Where possible, we have included BAT recommended levels in our mill environmental performance data in this Report.

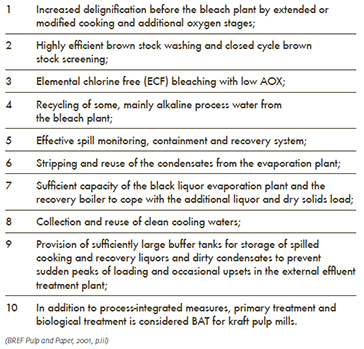

The following list shows BAT recommendations for bleached kraft pulp mill operations, with our mill meeting all recommendations.

The data provided is in accordance with GRI 3.1 environmental performance indicators. Disclosures include materials use, energy use, water, emissions and waste.

Figure 8: IPPC BAT RECOMMENDATION