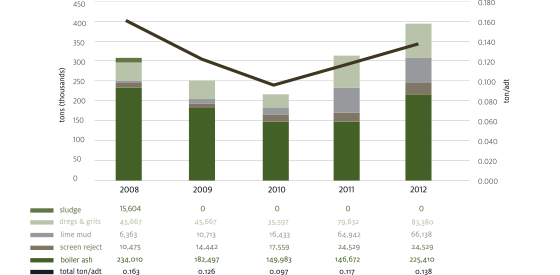

Figure 38: SOLID WASTE TO LANDFILL

Pulp and paper production generate significant waste streams. APRIL is committed to reducing, reusing and recycling these streams. APRIL currently operates a 14 hectare landfill site within our mill complex. This site incorporates modern leachate systems and is run according to best practice. Within the mill precinct, we face similar environmental challenges to other leading pulp and paper manufacturers around the world. Disposing of solid waste is an ongoing issue for our industry, whenever a high percentage of fuel used is biofuel.

Power boiler ash is a significant component of our total solid waste volume and has increased with mill production. In line with our industry counterparts around the world, we continue to work on alternative solutions to this problem.

The absence of sludge in landfill since 2009 is due to our biomass energy recovery initiative. We continue to develop alternative uses for our waste streams with the ultimate aim of having no waste sent to landfill.

Our landfill is for solid industrial hazardous wastes only; not for prohibited materials such as oil, fuel, lubricants or chemicals.

The mill site also includes an original landfill that was started in the mill development phase. Subsequently, remediation of this older landfill commenced in 2004.

This involved sealing the landfill and capturing the effluent generated from the site. Remediation was split into three phases, with 10 hectares remediated in 2005, a further 10 in 2006, and the remaining 14 hectares in 2009.

Remediation did not remove the material, but concentrated on leachate recovery and venting of methane. Remediation of this facility was undertaken with approval from the Indonesian authorities. A network of groundwater monitoring wells has been established around the remediated landfill and these are monitored on a quarterly basis with results reported to the regulator. Monitoring of this site continues.

A dedicated store for hazardous wastes (B3) is also located at the mill site. We have strict environmental procedures for operations and control of this facility and for appropriate disposal of hazardous waste.

The data reported in Figure 38 above is based on a comprehensive review of historical waste management data undertaken in late 2012.

Figure 39: SOLID WASTE BY TYPE, 2011-2012

Figure 39 above shows the relative proportions of solid waste generated over 2011 and 2012. Recovery Boiler number 5 has delivered significant environmental benefits in allowing fossil fuels to be replaced by biofuel.

It can be seen that boiler ash now represents just over half of all solid waste from our mill.

As we have continued to look for better solutions in solid waste management, we have examined the feasibility of using this material in road making and brick production. Other possible uses being explored in our industry include construction and concrete manufacture. We are working to find an alternative to landfill that is acceptable to our stakeholders, meets Indonesia’s regulatory requirements and constitutes a global best practice solution. The zero value for sludge is a result of this waste stream being redirected as part of our energy recovery program.

Our ongoing efforts to find a solution to the landfill issue led to a situation in late 2011 that resulted in APRIL having its valued green rating with Indonesia’s Program for Pollution Control, Evaluation, and Rating (PROPER) downgraded*. A green rating indicates that the mill environmental performance goes beyond the PROPER compliance guidelines.

When a boiler ash reusing initiative did not meet our expectations, we were compelled to dispose of the resultant solid waste in an emergency landfill site. That landfill area was not compliant with Ministry of Environment requirements. This led to our PROPER rating being downgraded from green to red*.

We immediately began remediation of the site and consequently, we have been upgraded to a blue rating*. We are on track to regain our PROPER green rating in due course.

Throughout this episode, we benefitted from constructive engagement with the Ministry of Environment, which again demonstrated to us that Indonesia’s authorities have both the regulatory means and the will to engage meaningfully on such matters, and that the Government’s system of annual compliance checks is effective.

On occasions when APRIL recognizes it has operated outside a regulation, immediate steps are taken to address the position. We are continuously working to further reduce our mill’s environmental impacts through modifications to plant and processes.