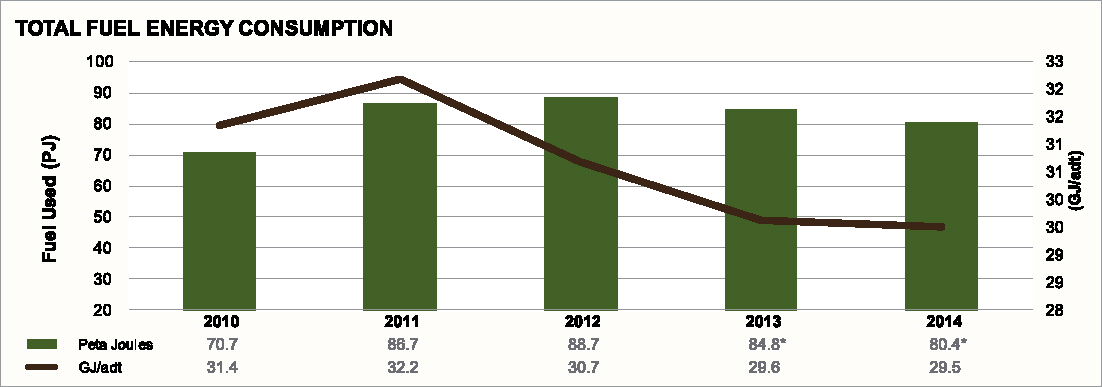

EFFICIENT USE OF ENERGY CONSUMPTION:

Decreased Energy Consumption Per Air Dry Ton (Adt)

The graph above shows improved efficiency as a result of effective energy conservation.

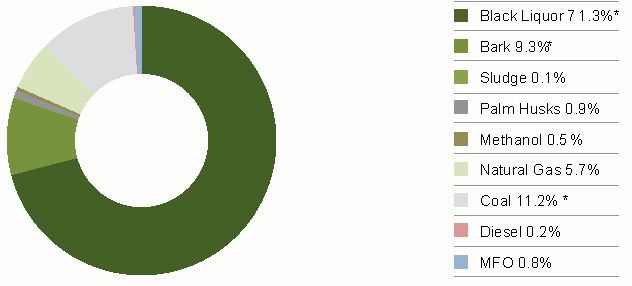

ENERGY CONTRIBUTION BY fUEL SOURCE

Biomass usage accounts for 82%* with 71.3%* of black liquor (based on the processing result of four units of recovery boilers). These recovery boilers have helped reduce our reliance on fossil fuels as well as cutting the indirect transport-related impacts of these fuels and reducing emissions from fossil fuels.

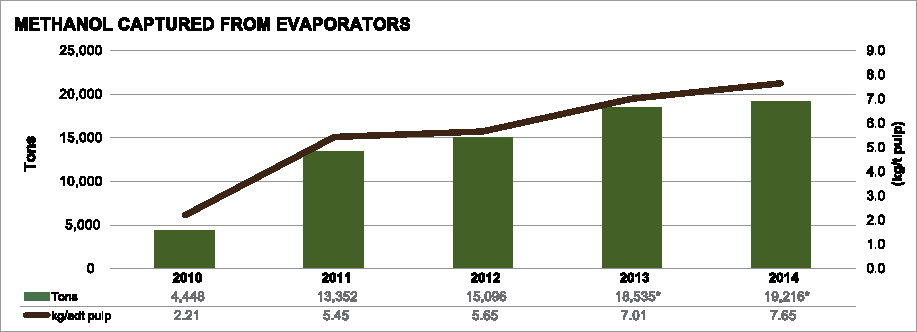

MORE FUEL CAPTURED FROM WASTE:

Our methanol capture project allows us to capture significant volumes of methanol from weak black liquor through a process of evaporation and distillation. Capturing more methanol results in cleaner gasses and condensate generation. This valuable biofuel is reused in our recovery boilers and lime kilns, replacing the use of fossil fuel.

REDUCING WOOD FIBER CONTENT THROUGH CAPTURE AND USE OF WASTE:

Our precipitated calcium carbonate (PCC) plant combines calcium hydroxide with waste CO2 that is captured from lime kilns. As an integrated pulp mill, we use lime kilns to convert calcium carbonate to calcium oxide or quicklime. This process generates a significant amount of CO2.

Rather than emit this gas as waste, we capture a portion of it to produce calcium carbonate on site.

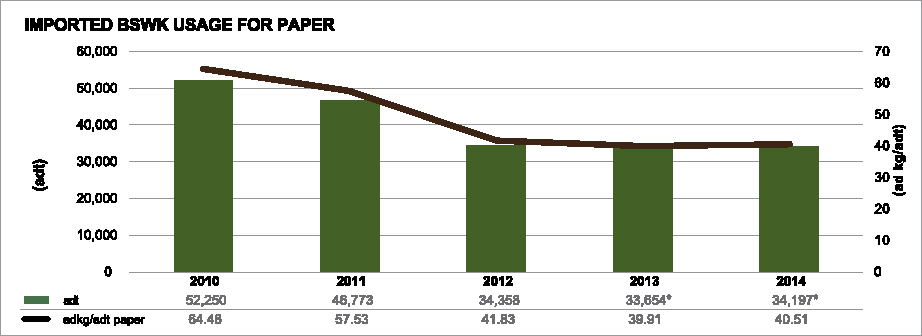

Another successful initiative involves a reduction in the amount of bleached soft wood kraft (BSWK) we require. BSWK is used to strengthen paper during paper making process. We have decreased our use of BSWK from 46,000 tonnes in 2011 to 34,000 tonnes in 2014. BSWK is imported from Chile and continuous reduction contributes to meaningful decrease in indirect transport-related CO2 emissions.

REDUCED MATERIAL IMPORTS:

IMPORTED BLEACHED SOFT WOOD KRAFT (BSWK) USAGE FOR PAPER

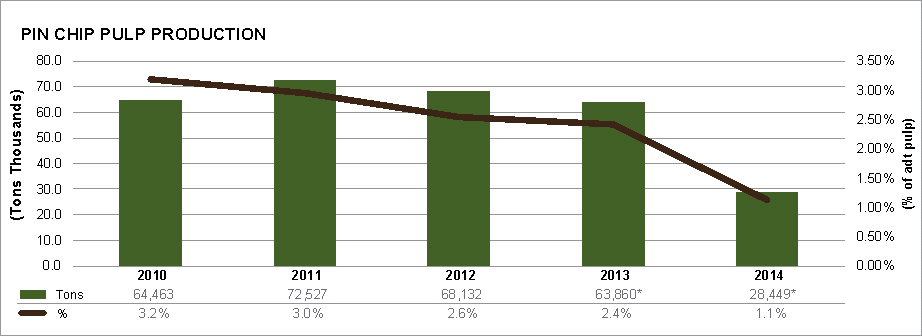

MAXIMIZING VALUABLE FIBER RESOURCES:

We invest in pin chip digester and chip classification screens for resources maximization and waste prevention. Fine wood particles are captured and converted to pulp. The graph above illustrated the decreasing production of pin chip as we increasingly use Acacia plantation fiber that produces less pin chip compared to mixed hardwood.