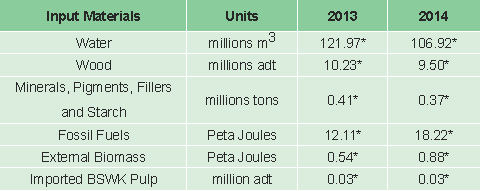

Our overall materials consumption is affected by factors such as operating efficiency and use of recycled materials.

As indicated in table below, we are now using more fossil fuel as a result of increasing Acacia plantation wood processing. Compared to mixed hardwood, Acacia plantation wood generates less black liquor and bark, elements to produce biofuel, and the gap is filled with fossil fuel – in this case, natural gas.

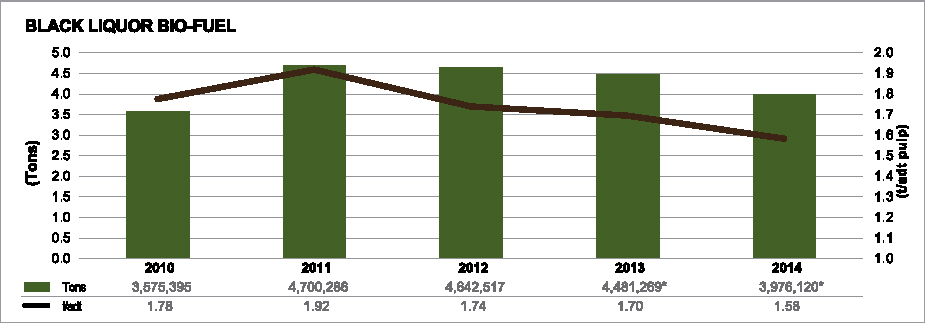

We continue to seek ways to find alternative source of biomass such as palm husk and palm shell to reduce the use of fossil fuel.

Due to our efforts to decreasing water consumption, water consumption in 2014 is greatly reduced by 15 million m3*, evaporated water was reduced by 7 million m3, and treated waste water was reduced by 8 million m3*.

RECYCLED MATERIALS

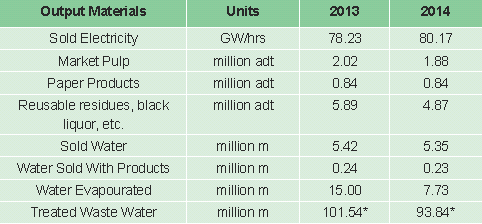

REPLACING FOSSIL FUEL WITH BIOFUEL

As indicated in the above chart, there is a significant decrease in black liquor production from 4.7 million tons in 2011 to 4 million tons in 2014. This is a consequence of processing more Acacia plantation wood that produces less black liquor compared to mixed hard wood. To meet energy requirement for product processing, we are sourcing more palm husks, bark as well as natural gas.

Biofuels such as palm husks and sludge are used to lessen our reliance on fossil fuels and fossil fuel generated carbon emission.