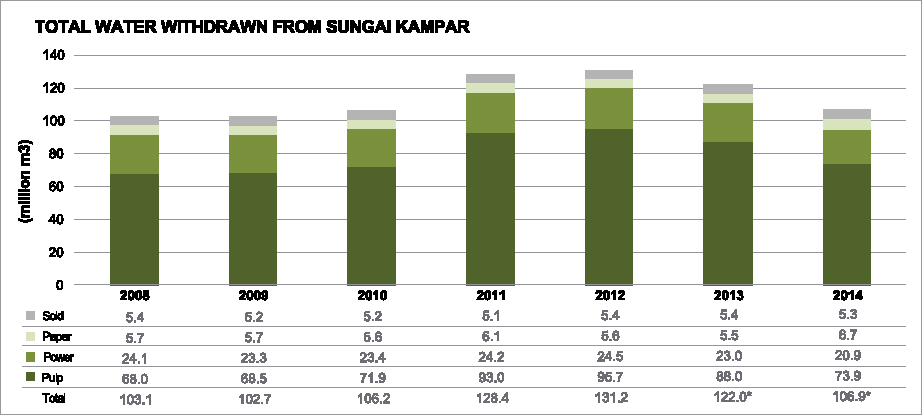

Our water source is the Kampar River that has an annual average flow of 219 cubic meters/second (1992 to 1996).

The river is used for transportation and fisheries as well as supplying water to local communities.

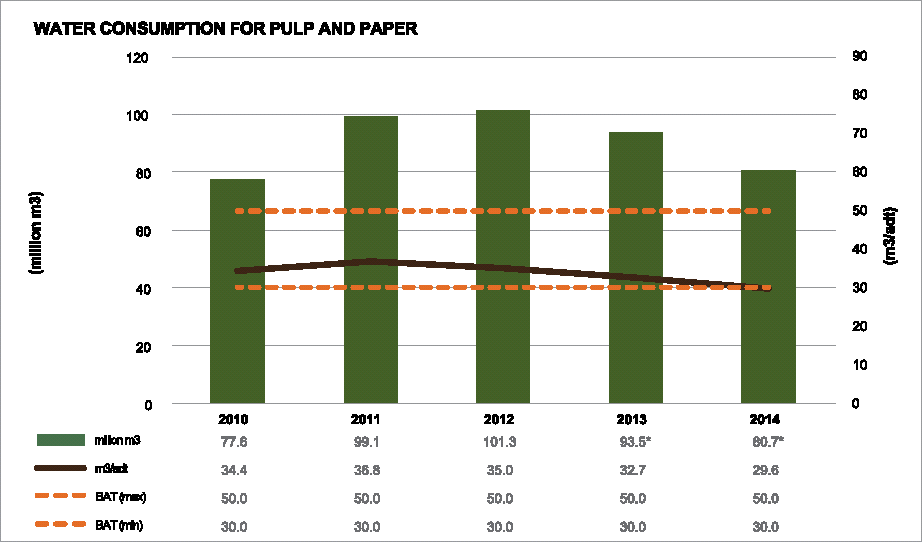

Water consumption is decreasing compared to 2012 and is closer to the BAT range as a result of water conservation initiatives.

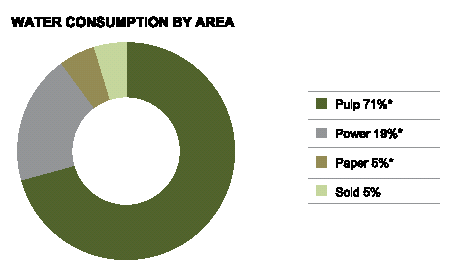

Water is used in almost every part of pulp and paper making process either as a solvent, for transporting materials through the mill and in power generation.

Pulp production consumes most of the water requirements. A small amount is used by households in the Kerinci township, our hotel, development facilities and our plantation nursery.

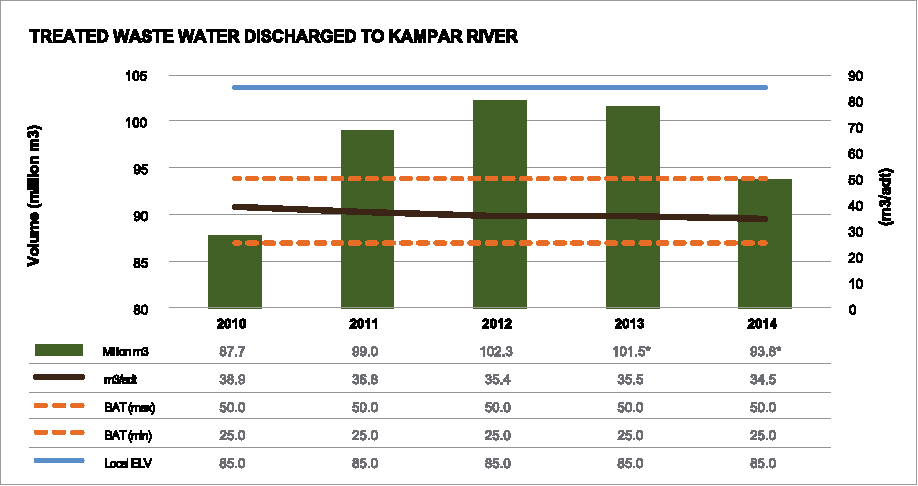

In 2014, we returned 94 million m3* of treated water to Kampar River or about 80% of our water withdrawal in the same year.

WASTE WATER TREATMENT:

Our mill has an on-site wastewater treatment facility and treats about 280,000 m3 of effluent per day. Suspended solids are removed and recovered for use in the power boiler.

WASTE WATER TREATMENT PROCESS SUMMARY:

Primary treatment: screening, primary clarifier, equalization, neutralization, cooling.

Secondary treatment: aeration, secondary clarifier, sludge handling, decanter centrifuge.

Post treatment effluent monitoring is carried out every shift by mill technicians and once a month by an accredited third party testing company and reported to regulators.

TOTAL RECYCLING OF WATER: G4 EN 10

Our mill uses high levels of internal recycling. Some production stages such as the paper machine forming section, involve very dilute processes that requires high water efficiency.

Our mill uses a counter current washing system in pulp washing stage, where condensates from an evaporator are used in washing pulp. Steam condensates from dryers is collected and reused as boiler feed water.