APRIL Group is committed to reducing, reusing and recycling. We operate a 14 hectares of landfill site within our mill complex that incorporate modern leachate systems and managed according to best practice.

In 2014, APRIL Group was awarded a blue rating by the Indonesia’s Program for Pollution Control, Evaluation and Rating (PROPER) from the Ministry of Environment. A blue rating indicates that the mill environmental performance is in full compliance with Indonesian regulations.

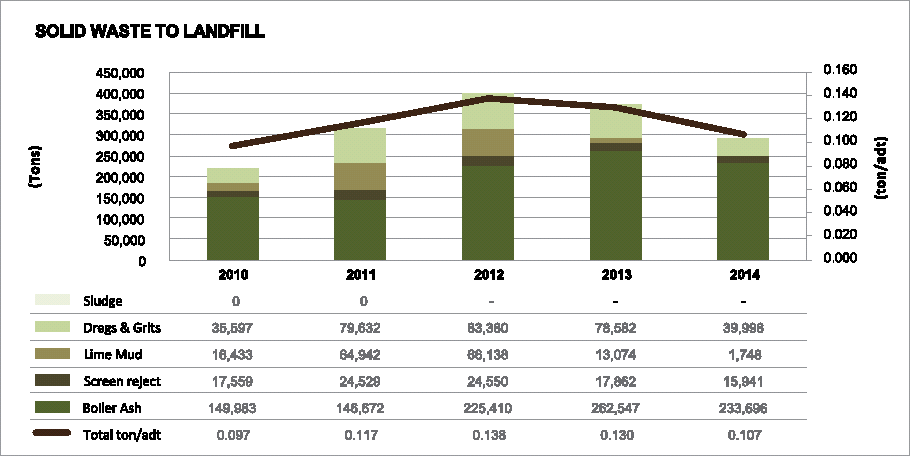

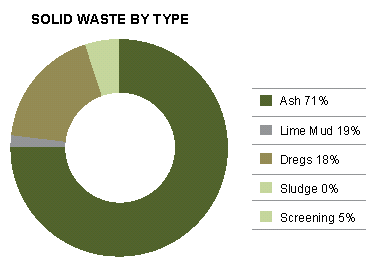

Similar to our industry peers around the world, we continue to work on alternative solutions to power boiler ash that is a significant component of our total solid waste volume.

Since 2009, our biomass energy recovery initiative resulted in the absence of sludge in landfill. Our end goal is to have no waste sent to landfill.

Our landfill is for solid industrial wastes only; no prohibited materials such as oil, fuel, lubricants or chemicals are sent to landfill.

A dedicated store for hazardous wastes (LB3) is also located at the mill site. We employ strict environmental procedures for operations and control of this facility and for appropriate disposal of hazardous waste.

We are exploring the possibilities of using boiler ash material in road making and brick production. Any such initiatives must meet Indonesia’s regulatory requirements and constitutes a global best practice solution.

Below is the relative proportion of solid waste generated over 2013-2014.

Acacia plantation fiber produces less black liquor compared to mixed hardwood (MHW) resulting in a decrease in biofuel production. To substitute black liquor, we increase the use of fossil fuel that impacted on the increase of ash.

As APRIL Group increases the use of plantation wood and progresses toward zero MHW use, we continue to seek innovative ways to decrease fossil fuel use by increasing externally-sourced palm husks and bark that are to be processed as biofuels.

Meanwhile, zero value of sludge is a result of waste stream being re-directed as part of our energy recovery program.