Pulp Products

APRIL Group is a world leading pulp supplier and uses advanced manufacturing processes to produce pulp of premium quality. Our plantation pulp products are PEFC certified, as the fiber used in production is sourced from sustainably managed plantation and sources which uphold ecological, economic and social values.

Pulp is the basis of many paper products, from the corrugated boards used in factories to daily necessities like paper, tissue, tea bags and magazines. APRIL produces bleached acacia kraft pulp (BAKP), which has a wide variety of applications due to its excellent formation, opacity and fiber properties. Due to these qualities, it is suitable for all paper grade segments. The company is also able to provide customized products focusing on specific end-uses for market pulp, such as tissue and specialty segments.

Other than paper grade pulp, APRIL also produces rayon grade pulp that is supplied to Sateri and Asia Pacific Rayon, which are also business groups under RGE, along with APRIL. Rayon grade pulp is produced using the prehydrolysis kraft cooking process, and the final product is called AE pulp.

How is pulp made?

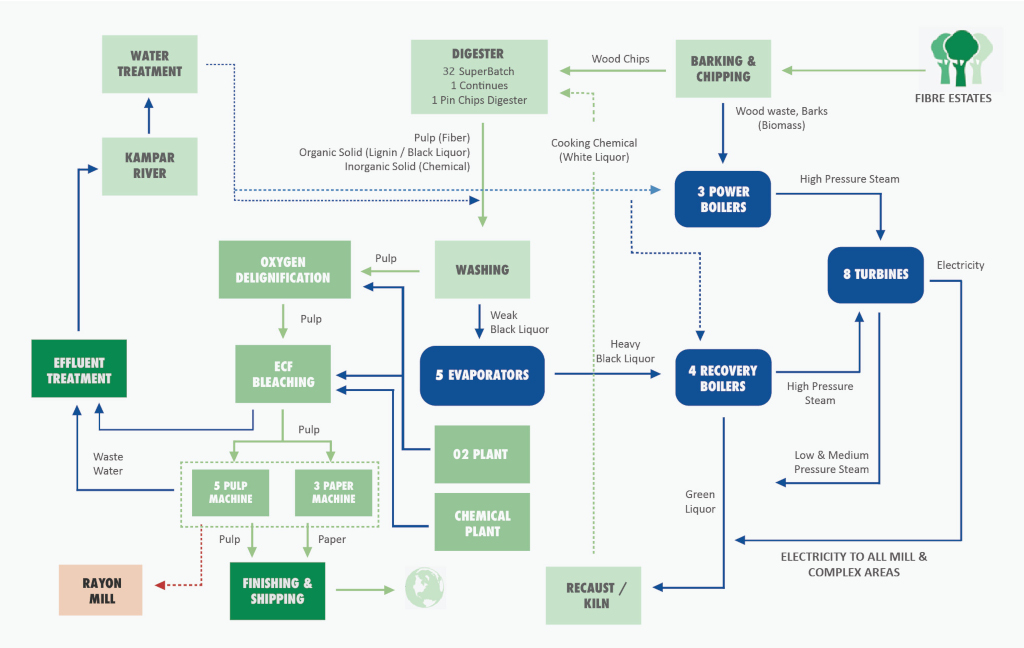

To make pulp, wood is chipped and screened to create chips of the desired size and then cooked with a chemical called white liquor to produce a mixture in a pulp digester. The purpose of this stage is to release the natural glue that bonds wood fibre. The cooked pulp called brown stock pulp is washed, screened and undergoes further processing and bleaching to ensure that the final product is whiter and more absorbent. The pulp making process is fully automated, and uses state of the art equipment.

The principal by-product from the cooking of wood chips is lignin, which is in the form of black liquor. This is treated to become highly concentrated liquor, before it can be used as biofuel in the boilers to generate steam and power to support the production process. After utilization of black liquor for energy, by-product can also then be recovered into green liquor, which then will be chemically processed to produce white liquor again. This is what is called the kraft recovery cycle, a closed cycle with three main functions - to eliminate waste material (black liquor), to recover pulping chemicals (NaOH and Na2S), and to generate steam and power.

Bleached slurry pulp is also supplied to the pulp machines, and is converted into dried pulp. This can then be further processed to produce paper. When the pulp is dried, finished and baled, it is shipped to customers to make a wide variety of end products.